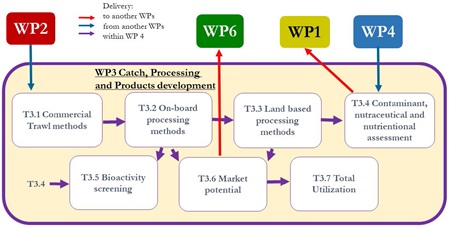

Overview of tasks in work package 3

The tasks in work package 3 will combine research on effective trawl methods and on board stabilization of the mesopelagic catch, with processing and evaluation of the biomass towards commercial products. The possible products are food, feed and biotechnological products. The commercial potential of possible products will be evaluated. The trawl methods will also be evaluated together with commercial fisheries.

Flows of information and data to, from and within work package 3. Click to see larger version

Task 3.1 Develop effective and sustainable commercial trawl methods

Lead: Sintef Ocean AS

New trawls will be developed in collaboration with Norwegian and Irish fishing vessel partners to ensure the methods are applicable to a larger fleet, and with focus on reducing the energy consumption during mesopelagic trawling. Key development goals for sustainable trawling method are developing deep fishing (day fishing) and shallow fishing (night fishing) trawl methods and sustainable herding mechanisms for improving the fishing efficiency.

Existing mesopelagic sampling trawls will be demonstrated, and the results of trawling experiments conducted in 2016, 2017 and 2018 will be evaluated. The results include both the effects of trawl design and species specific (Maurolicus muelleri and myctophids) behaviour in relation to the trawl.

In this task specialized trawls will be developed and tested for shallow and deep fishing considering previous knowledge and experience about trawl design and fish behaviour (Grimaldo et al., 2018; see bottom of page). Continuous codend pumping systems for efficient trawling and better catch quality will be developed and tested. Trawl design will be tested for minimum drag versus trawl mouth opening area and mesh size as well as minimum time to operational depth. Active herding mechanisms of mesopelagic fish into the centre of the trawl can potentially increase catch rates, and thus fishing efficiency. Herding by light and ultrasound are potential alternatives for concentrating mesopelagic fish. Therefore, the effect of light colour and light intensity, as well as ultrasound, will be investigated.

Task 3.2 Develop on-board processing methods

Lead: Nofima AS

The most profitable on-board (Task 3.2) and land-based (Task 3.3) processing of mesopelagic catches will be established through testing of relevant technologies in combination with the development of potentially marketable products from the biomass. Developed on-board processing methods will be paired with on-land methods of processing and further refinement in order to match food, feed or biotechnology applications. Initially the variation in raw material quality and nutrient content will be determined. Then the nutrient contents (proteins, lipids and mineral/ash) of caught biomass will be determined.

Lipid content has been demonstrated to vary with season and species. Special attention will be given to investigating mesopelagic fish as a new lipid and long-chain polyunsaturated fatty acids (LC-PUFA) source.

Available application of the proteinaceous or mineral fractions will be determined, and in addition, autolytic activities in the caught biomass and microbial communities present and associated with the catch will be analysed for utilization towards biotechnological or other applications. Previous analyses have revealed that mesopelagic species easily deteriorate after harvest (Olsen and Torrissen, 2015; see bottom of page). Tissue degradation caused by endogenous enzymes (autolysis) releases low molecular weight compounds like amino acids/peptides, nucleotides and fatty acids which in turn promotes microbial growth and spoilage (Samuelsen and Otherhals 2015; see bottom of page). The high lipid and long-chain polyunsaturated fatty acid content is susceptible to oxidation and these processes may be further influenced by the treatment and storage conditions. With the long distance to the fishing areas, these challenges make it desirable to have on-board processing of mesopelagic harvests. However, potential bioactive properties can add value to the raw material and make land-based processing economic feasible.

It is expected that the major part of mesopelagic fish resources will be used for production of fishmeal and fish oil—marine ingredients—primarily to be used in feed for aquaculture and as part of the food chain. High contents of omega 3 fatty acids (including EPA & DHA and phospholipids) can also make the catch valuable as nutraceuticals.

Mesopelagic fish contain variable amounts of wax esters that may interfere with nutrient digestion in fish and/or cause problems with fat extraction during processing (Phleger et al 1999, Samuelsen and Oterhals 2015; see bottom of page).

Previously onboard processing technologies that has been tested are thermic separation, hydrolysis and production of silage. In addition, further technologies on-board will be tested including microwave volumetric heating, either for product stabilization or enhancement of enzymatic hydrolysis, the later also assisted by thermosonication. Plasma activated water could also be considered as a control step to avoid microbial/enzyme degradation for high value products.

Task 3.3 Develop land-based processing and refinery methods

Lead: Nofima AS

Potential resources from the mesopelagic catch include fish meal and oils that can be used in aquaculture feed. Protein and peptide concentrates from the mesopelagic catch can also be produced from the biomass. In addition, the catch can be specifically processed, by hydrolysis or other methods, to create products like nutraceuticals including long-chain polyunsaturated fatty acids, bioactive peptides, collagen products, or low molecular components with possible uses as functional food or feed, cosmetics, health food, or other applications. The biomass may also contain biotechnological products including antioxidant components, antimicrobial activity, high enzymatic activity, or unexplored microorganisms.

Different processes are available for the refinement, and the yield of high-value components will guide process selection (Vang et al 2017, Aspevik et al 2017; see bottom of page). Processes will be tested including hydrolysis with selected enzymes, microwave, ultrasound, plasma and CO2 extraction. Based on the most promising land-based or onsite processing technique the processing factors (change in yield, contaminant level, bioactivity from catch to finished products) for selected components will be established.

Task 3.4 Contaminant, nutraceutical and nutritional assessment in different processing methods

Lead: Institute of Marine Research

In order to be evaluated for food or feed, the level of unwanted substances must be determined. The EU has set legal maximum residue limits (MRL) for unwanted substances in feed ingredients and animal feed in order to ensure animal health and food safety throughout a food production chain (e.g. aquaculture production). Compliance with this EU legislation is a prerequisite for novel feed ingredients to be used in aquafeeds.

Earlier trials have shown that the processing of the mesopelagic raw material caused an increase in environmental contaminants such as cadmium (El-Mowafi A. et al., 2010; see bottom of page), causing cadmium levels to exceed the former EU legislation for feed ingredients. A potential increase, or removal/reduction (e.g. Oterhals and Kvamme, 2013; see bottom of page), of contaminants strongly depends on the selected processing approach. This work package will assess the change in contaminant level during the processing of mesopelagic catch.

In addition to known contaminants under current EU legislation, the catch will also be screened for possible novel marine contamination challenges such as micro-plastics (EFSA, 2014; see bottom of page), marine biotoxins (ciguatoxin, pinnatoxins) (Reverte et al., 2014; see bottom of page), and marine-specific metalloid forms such as arsenobetaine.

In addition to contaminants, mesopelagic fish can contain anti-nutrients, such as erucic fatty acids (EFSA, 2016; see bottom of page). Feral catch from previous trawls has been tested for some of these toxins, including dioxins, PCBs, PAH, pesticides, and heavy metals (lead, cadmium, mercury and arsenic). These tests demonstrated values below the EU limit, however these levels have to be evaluated together with the developed processing methods because the processing can alter the nutritional value, such as fatty acid composition, or the quality, and could produce bio-active products that have nutraceutical properties.

Task 3.5 Bioactivity screening of raw and processed biomass

Lead: TEAGASC - Agriculture and Food Development Authority

Upon determining the applicability of the biomass for food or feed, bioactivity promoting heart health benefits will be tested in raw and processed biomass. Validated methods will be employed to identify bioactivity with potential heart health, antioxidant, sarcopenia, gut health, and mental health benefits in order to evaluate possible uses of the biomass in health foods or nutraceuticals.

Different processing methods will result in different bioactive compounds, and selected processing methods that are considered feasible and effective will be tested towards bioactivity. Antimicrobial screening and evaluation of using the significant autolytic enzymatic activity towards biotechnological applications, both mixed and fractionated biomass will be processed and evaluated.

Tasks in this work package will be continually evaluated across tasks and work packages in order to create the most synergies. These analyses will determine if there are additional benefits to the biomass that can lead to higher value products from the mesopelagic catch. These possible nutraceutical properties will be validated on possible bioactive indications and biotechnological products from the processes mesopelagic catch.

Task 3.6 Evaluating market potential and needs

Lead: Fundacion AZTI – AZTI Fundazioa

Based on results from on-board and land-based processing and testing, a variety of products can be identified and must be evaluated based on market potential, energy consumption, and cost of production. Techno-economic feasibility will be determined and evaluated in order to determine the applicability of different processes against market potential.

The product and market evaluation will be performed in a transactional collaboration between process, analytics and industry experts to ensure the right products are produced from the caught biomass. The market evaluation will continue into the scaling in task 3.7, and all inputs will be important factors in the market evaluations. The social impacts of these processes will also be evaluated in work package 6.

Task 3.7: Total utilization - Scaling of processes and market prototype testing

Lead: Nofima AS

To ensure all processes are marketable, scaling of selected processes will be performed in available appropriate infrastructure. Prototype products can then be tested in the market. This industrial scale testing can be performed both for food and feed grade products using infrastructure available to the consortium partners. Quality and contents of the fresh biomass will be combined with state-of-the-art bioprocessing techniques to produce the highest value and best use of the resource.

These factors include energy processing costs, infrastructure investment costs, and market acceptance and possibility analysis. The data obtained will be analysed using cluster analysis to identify the optimal combination of value, usage and cost. A step-wise isolation of components for various uses can be applied in order to ensure sustainability. In addition, the processes to be scaled are the most promising one to two processes based on the different methods tested in this procedure.

References

Aspevik et al 2017Aspevik T., et al. 2017.Valorization of Proteins from Co- and By-Products from the Fish and Meat Industry, Top Curr Chem. 375(3):53.

EFSA 2014. Update on EFSA’s activities on Emerging Risks 2012-20131 European Food Safety Authority2. EFSA supporting publication 2014:EN-585.

EFSA 2016. Erucic acid in feed and food. EFSA Journal 2016;14(11):4593.

El-Mowafi A., Nanton, D., Berntssen, M.-H.G., 2010. Evaluation of lantern fish (Benthosema Pterotum) as marine source in fish feeds: nutrient composition and contaminants assessment. Proc. of the 3rd Global Fisheries & Aquaculture Research Conference.

Grimaldo, E., et al. 2018. Experimental fishery and utilization of mesopelagic fish species and krill in the Northeast Atlantic –Report of the ICES-FAO Working Group on Fishing Technology and Fish Behaviour (WGFTFB), ICES CM 2018/EOSG:12. 234 pp.

Olsen, R.E., Torrisen O. 2015. Mesopelagic fish – a potentially new source for marine proteins and fat, 2nd international conference on global food security, Itchaca, NY, USA, 2015.

Oterhals, A., Kvamme, B., 2013. Optimization of an oil leaching process to reduce the level of dioxins and dioxinlike PCBs in fishmeal. Journal of the Science of Food and Agriculture 93, 1649-1659.

Phleger C.F., Nelson M.M., Mooney B.D., Nichols P.D. 1999, Wax esters versus triacylglycerols in myctophid fishes from the Southern Ocean. Antarctic Sci 11(4):436-44.

Reverte, L., Solino, L., Carnicer, O., Diogene, J., Campas, M. 2014. Alternative Methods for the Detection of Emerging Marine Toxins: Biosensors, Biochemical Assays and Cell-Based Assays. Marine Drugs 12, 5719-5763.

Samuelsen, T. A. and Oterhals Å., 2015. Water‐soluble protein level in fishmeal affects extrusion behaviour, phase transitions and physical quality of feed, Aquaculture Nutrition, 22(1)120-133.

Vang, B., et al. 2017. Nofima: Peptide recovery and commercialization by enzymatic hydrolysis of marine biomass. Biocatalysis: An Industrial Perspective, ed. Gonzalo de Gonzalo. Royal Society of Chemistry.